Vastuullisuus

Vastuullinen toiminta ja kestävä kehitys ovat keskeinen osa Componentan liiketoimintaa

Yhtiön arvot – avoimuus, rehellisyys ja arvostus – sekä strategia ja toimintatavat luovat perustan yhtiön vastuulliselle toiminnalle. Vastuullisuus huomioidaan yhtiön lyhyemmän ja pidemmän aikavälin suunnittelu- ja kehitystyössä. Componentan johto asettaa vuosittain vastuullisuustavoitteet, joiden kehittymistä seurataan ja analysoidaan säännöllisesti.

Componentan vastuullisuustoimenpiteistä on luettavissa myös uusimmasta vuosikatsauksestamme.

Componenta tunnistaa liiketoimintansa vaikutukset ympäröivään yhteiskuntaan ja sidosryhmiinsä. Yhtiön toimialalla korostuvat etenkin vastuu ympäristöstä sekä henkilöstöstä huolehtiminen. Tuoteportfolion näkökulmasta erityisesti valukomponenttien tuotanto on energiaintensiivistä, ja tuotantoprosessissa syntyy sivutuotteena myös huomattava määrä ylijäämähiekkaa ja pölyä. Toimiala on luonteeltaan henkilöstöintensiivinen, joten sekä henkilöstökustannukset että investoinnit henkilöstön hyvinvointiin ja osaamiseen vaikuttavat merkittävästi yhtiön menestymiseen. Yhtiö kunnioittaa työntekijöidensä oikeuksia, yhdistymisvapautta sekä kollektiivista neuvotteluoikeutta ja harjoittaa liiketoimintaansa turvallisissa työskentelyolosuhteissa. Yhtiössä on nollatoleranssi pakkotyötä, lapsityövoimaa ja syrjintää kohtaan.

Ympäristövastuu

Componentan laatu-, ympäristö-, työterveys- ja -turvallisuuspolitiikat ohjaavat laatuun ja ympäristönäkökohtiin liittyviä toimenpiteitä. Jokaisessa tuotantoyksikössämme on kolmansien osapuolten sertifioimat laatu- ja ympäristöjärjestelmät.

Componentan tärkeimmät tavoitteet ympäristövastuun osalta ovat päästöjen ehkäisemisen lisäksi energiatehokkuus ja energiankäytön vähentäminen sekä jätteiden synnyn vähentäminen ja hyötykäyttö. Kierrätysmateriaalin käyttö tuotannon raaka-aineena on ollut yhtiölle jo pitkään itsestäänselvyys. Myös Componentan valmistama lopputuote voidaan kierrättää. Componentalla jokainen investointi arvioidaan myös sen ympäristövaikutusten osalta.

Componentan merkittävimmät ympäristövaikutukset liittyvät pääasiassa valukomponenttien tuotannon energiankulutukseen, tuotantotoiminnan sivutuotteena syntyvään ylijäämähiekkaan ja pölyyn, sekä tuotantoyksiköiden toiminnasta mahdollisesti aiheutuviin päästöihin. Componentalla jokainen merkittävä investointi arvioidaan myös sen ympäristövaikutusten osalta. Uuden teknologian käyttöönotto sekä muutokset tuotantotavoissa voivat vaikuttaa myönteisesti muun muassa energian ja raaka-aineiden käyttöön ja päästöihin.

Componentan valimoissa raaka-aineen sulatus ja sulan kuumanapito kuluttavat paljon energiaa, minkä vuoksi Componenta on suuri energiankäyttäjä. Mahdollisella paikallisella energian hinnan nousulla tai energiankäytön verotuksen kiristymisellä voi olla huomattavia vaikutuksia Componentan toimintaedellytyksiin. Yhtiön toimintaedellytyksiin vaikuttaisivat heikentävästi myös jätemaksujen ja -verojen korotukset. Keskeisiä riskitekijöitä toiminnalle ovat lisäksi mahdolliset ympäristölupamääräysten tai päästörajojen tiukentamiset.

Ympäristön pilaantumisen ehkäiseminen on keskeistä Componentalle, sillä ympäristön pilaantumista mahdollisesti aiheuttava toiminta on nykylainsäädännön tiukkuuden ja laajuuden vuoksi merkittävä taloudellinen riski. Ympäristönsuojelusääntöjen rikkominen vaikuttaisi negatiivisesti Componentan toimintaan myös yhtiön maineeseen kohdistuvan haitan muodossa. Componenta on sitoutunut noudattamaan kaikkia soveltuvia paikallisia lakeja ja määräyksiä. Yhtiön tavoitteena on varmistaa, että toiminta jatkuu häiriöttä, toiminnan laatu pysyy hyvänä, ja toiminnasta ympäristölle tai lähistön asutukselle koituvat vaikutukset pidetään mahdollisimman vähäisinä.

Componentan tärkeimmät tavoitteet ympäristövastuun osalta ovat päästöjen ehkäisemisen lisäksi energiatehokkuus ja energiankäytön vähentäminen sekä jätteiden synnyn vähentäminen ja jätteiden hyötykäyttö. Componenta seuraa aktiivisesti energiankäyttömääriään ja energian säästämiseksi tehdään jatkuvaa työtä kaikissa tuotantoyksiköissä. Energiankäyttöä pyritään tehostamaan esimerkiksi kehittämällä ja parantamalla laatua, sitoutumalla vastuulliseen energiankäyttöön sekä menetelmäsuunnittelulla ja tarvittavien energiakatselmointien avulla.

Rautavalimoissa tuotantomäärät ja kuormituksen tasaisuus vaikuttavat keskeisesti suhteelliseen energiankäyttöön ja energiankäytön tehokkuuteen, sillä tuotantovalmiuden ylläpitoon, kuten sulan kuumanapitoon, tarvittava energian määrä ei vähene suoraan tuotannon mahdollisen pienentymisen myötä. Tuotteen ja tuotannon suunnittelu, materiaalivalinnat sekä laadun optimointi ovat merkittäviä tekijöitä tuotteen elinkaarenaikaisten ympäristövaikutusten kannalta. Mitä parempaa laatua Componentan tuotantoprosessissa syntyy, sitä vähemmän syntyy hukkakappaleita, ja raaka-aineita, energiaa ja resursseja kuluu vähemmän. Componentan valimoiden toiminta on vahvasti kiertotalouteen perustuvaa, sillä valukomponenttien pääraaka-aine on suureksi osaksi kierrätysmetallia.

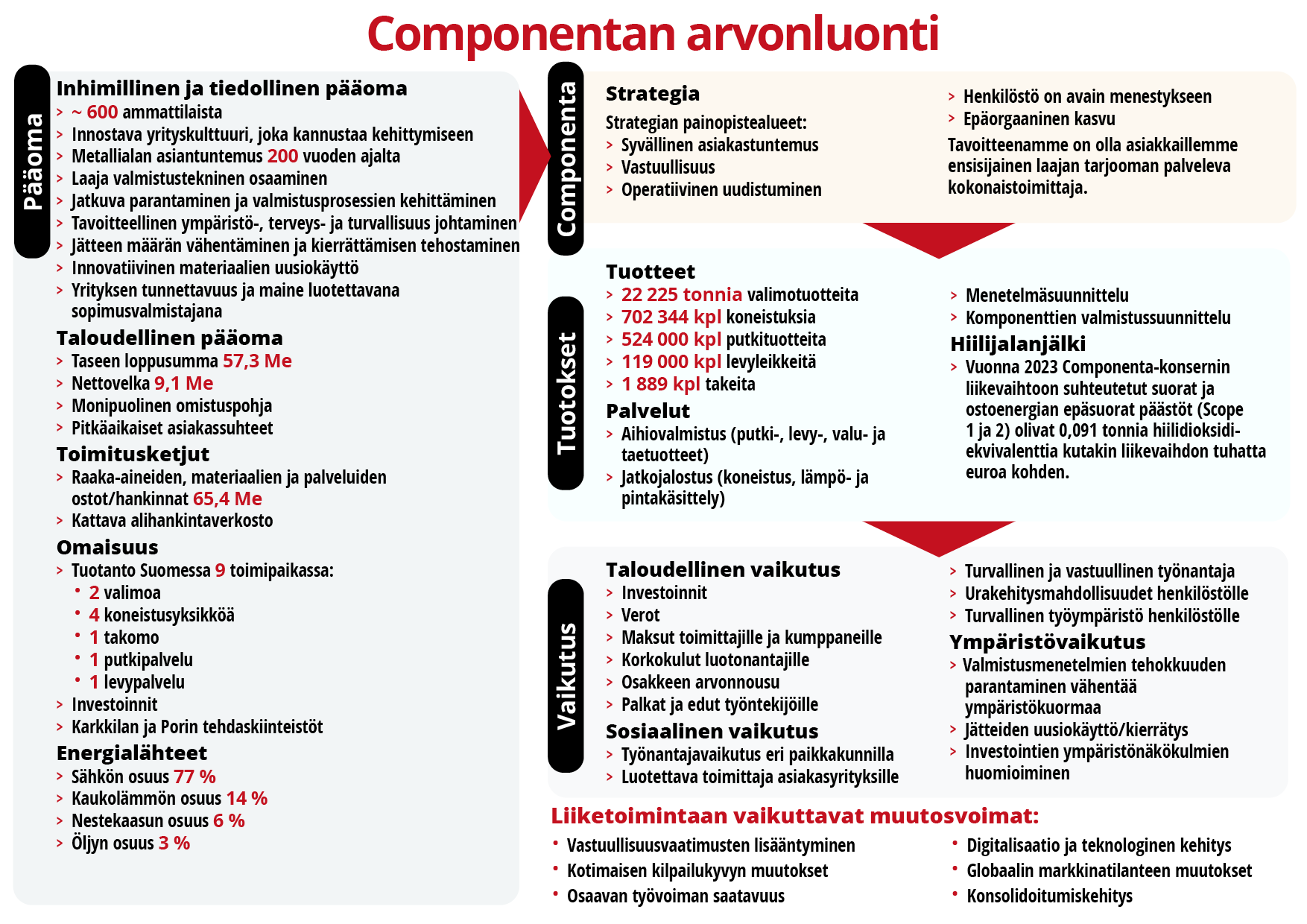

Componenta-konsernin hiilijalanjälki

Componenta-konserni laski ensimmäisen kerran hiilijalanjälkensä vuoden 2021 tietoihin perustuen vuonna 2022. Päästölaskenta on tehty GHG Protocol Corporate Accounting and Reporting -standardin sekä Corporate Value Chain Accounting and Reporting -standardin mukaisesti. GHG-protokollan mukaan kasvihuonekaasupäästöt luokitellaan kategorioihin: yhtiön suorat päästöt (Scope 1), ostoenergian epäsuorat päästöt (Scope 2) ja muut epäsuorat päästöt (Scope 3).

Vuonna 2023 Componenta-konsernin liikevaihtoon suhteutetut suorat ja ostoenergian epäsuorat päästöt (Scope 1 ja 2) olivat 0,091 tonnia hiilidioksidiekvivalenttia kutakin liikevaihdon tuhatta euroa kohden. Liikevaihtoon suhteutettuna päästöt nousivat vuodesta 2023 ja ne olivat vertailuvuonna 0,086 tonnia hiilidioksidiekvivalenttia kutakin liikevaihdon tuhatta euroa kohden. Vuoden 2023 alhaisempi sähkönhinta vuoteen 2022 verrattuna vaikutti liikevaihtoon suhteutettujen päästöjen nousuun edellisvuoteen verrattuna, koska alhaisempi sähkön hinta johtaa alhaisempaan liikevaihtoon. Sähkönhinnan muutokset siirtyvät konsernissa myyntihintoihin indeksin avulla. Suurin osa Componenta-konsernin kasvihuonekaasupäästöistä aiheutuu valimotoiminnasta, koska valimoissa raaka-aineen sulatus ja sulan kuumanapito kuluttavat paljon energiaa. Suurin osa Componentan kasvihuonekaasupäästöistä aiheutuu muista epäsuorista päästöistä (Scope 3), kuten raaka-aineista ja kuljetuksista.

Componentan päästöjä on mahdollista vähentää muun muassa siirtymällä uusiutuvaan tai fossiilittomaan energiaan. Componentan vaikutusmahdollisuudet raaka-ainepäästöihin ovat rajalliset. Raaka-aineiden valmistamisen päästöt riippuvat toimittajien valitsemista tuotantoprosesseista, käytetystä energiamuodosta, logistiikasta sekä yleisesti metalliraaka-aineiden valmistamisen kehittymisestä ympäristöystävällisemmäksi. Vuonna 2023 Componenta valmisteli ilmastotiekarttaansa.

Sosiaalinen vastuu ja työntekijöihin liittyvät seikat

Componentan sosiaalisen vastuun johtaminen perustuu henkilöstöpolitiikkaan, johtamisen periaatteisiin sekä yhtiön arvoihin. Componentan henkilöstöpolitiikan mukaisesti henkilöstövalinnoissa rekrytoinnin yhteydessä sekä urakierron eri vaiheissa korostuvat osaaminen, kokemus ja motivaatio. Palkka- ja palkitsemisjärjestelmät ovat oikeudenmukaisia, selkeitä ja kilpailukykyisiä. Componentan henkilöstöpolitiikan mukaisesti kaikkia kohdellaan yhdenvertaisesti ja tasa-arvoperiaatteita noudattaen. Componentan tasa-arvosuunnitelma ja yhdenvertaisuussuunnitelma päivitetään vuosittain työyhteisön kehittämissuunnitelman yhteydessä. Componentalla on myös erillinen ohjeistus häirintään ja epäasialliseen käytökseen liittyen.

Työntekijöiden käytössä on myös sisäinen ilmoituskanava väärinkäytöksistä ja esimerkiksi mahdollisista syrjintäepäilyistä raportoimiseen.

Componenta tarjoaa tasapuolisesti sekä suomalaisille että Suomeen muuttaneille työikäisille työntekijöille työtä, turvallisen työympäristön ja tasa-arvoiset mahdollisuudet kehittyä työssään. Componenta on monipuolinen työpaikka ja vuonna 2023 konsernissa työskenteli henkilöstöä 14 eri kansallisuudesta. Naisia Componentan työntekijöistä on 17 %. Componenta perehdyttää ja kouluttaa kaikki yritykseen tulevat työntekijät omiin työtehtäviin ja työn turvallisuusvaatimuksiin. Yritys kannustaa jatkuvaan kehittymiseen, ammattitaidon kasvattamiseen ja huolehtii työhyvinvoinnista ja sen ylläpidosta.

Sosiaalista vastuuta sekä työntekijöihin liittyviä seikkoja koskevat riskit painottuvat teollisessa toimintaympäristössä etenkin työntekijöiden työterveyteen ja työtapaturmiin. Fyysisesti kuormittava työ tuotantoympäristössä edellyttää panostusta työturvallisuuteen ja terveellisiin työtapoihin, joten Componentalla henkilöstön hyvinvointia edistetään kehittämällä työturvallisuutta ja tukemalla työkykyä ylläpitävää toimintaa. Etenkin pitkäaikaiset sairauslomat ja pitkäaikaisia sairauslomia aiheuttavat työtapaturmat ovat riskitekijöitä toiminnalle, sillä inhimillisen tiedon ja osaamisen korvaaminen ja uusiminen voi kestää pitkään. Lisäksi merkittävät sairauspoissaoloista ja tapaturmista aiheutuvat välittömät ja välilliset kustannukset voivat vaikuttaa haitallisesti Componentan taloudelliseen tuloksentekokykyyn.

Työntekijöiden työterveyteen liittyviä riskejä hallitakseen Componenta panostaa jatkuvasti sairauspoissaolojen ennaltaehkäisyyn sekä sairauspoissaolojen keston lyhentämiseen. Erityisenä tavoitteena on työtapaturmia koskevien riskien tehokkaampi tunnistaminen ja tämän myötä työtapaturmien vähentäminen. Nämä seuranta- ja kehityskohteet ovat myös tiiviisti sidoksissa toisiinsa.

Onnettomuusriskien minimoimiseksi ja ennaltaehkäisemiseksi Componentan tuotantoyksiköissä järjestetään säännöllisesti sekä turvallisuuskävelyitä että työturvallisuuskoulutuksia ja huolehditaan siitä, että henkilöstöllä on päivitetyt, sopivat ja riittävät työkalut käytössään. Kaikilla yksiköillä on yhteinen työsuojelun toimintaohjelma, ja yksikön päälliköt valvovat tavoitteiden toteutumista yksiköissä.

Ihmisoikeuksien kunnioittaminen

Componentan raaka-aine- ja toimitusketjut ovat globaaleja ja yhtiö tunnistaa vastuunsa olla omalta osaltaan myötävaikuttamassa ihmisoikeuksien kunnioittamiseen arvoketjussa. Myös Componentan asiakkaat edellyttävät, että arvoketjussa noudatetaan yleismaailmallisesti tunnustettuja eettisiä periaatteita. Liikekumppanien valintaan vaikuttavat kuitenkin useat eri tekijät, mukaan lukien sitoutuminen Componentan toimittajien ja alihankkijoiden eettisiin ohjeisiin (Supplier Code of Conduct).

Ihmisoikeuksien rikkomiseen liittyvät merkittävimmät riskit kohdistuvat Componentan tuotteiden toimitusketjussa toimiviin tavarantoimittajiin ja alihankkijoihin, joiden sijaintimaassa ei voida taata kansainvälisesti tunnustettujen ihmisoikeuksien tai työntekijöiden perusoikeuksien toteutumista. Mahdolliset ihmisoikeuksien ja työntekijöiden perusoikeuksien loukkaukset arvoketjussa aiheuttavat etenkin yhtiön maineeseen kohdistuvia riskejä.

Componenta pyrkii eettisten ohjeidensa mukaisesti siihen, että sen tuotteiden toimitusketjussa kunnioitetaan ihmisoikeuksia eikä edistetä konflikteja. Toimittajilta ja alihankkijoilta edellytetään voimassa olevien lakien ja määräysten noudattamista. Componentalla on toimittajille ja alihankkijoille tarkoitetut eettiset ohjeet. Toimittajien ja alihankkijoiden tulee myös tukea ja kunnioittaa kansainvälisesti tunnustettuja ihmisoikeuksia, jotka on määritelty YK:n ihmisoikeuksien yleismaailmallisessa julistuksessa, sekä Kansainvälisen työjärjestön (ILO) määrittelemiä työntekijöiden perusoikeuksia. Lisäksi toimittajien ja alihankkijoiden on noudatettava toiminnassaan Componentan edellyttämiä laatu- ja ympäristöstandardeja.

Componenta kunnioittaa ihmisoikeuksia omassa vaikutuspiirissään ja harjoittaa liiketoimintaansa läpinäkyvällä ja luotettavalla tavalla. Ihmisoikeuksien kunnioittamisen periaatteiden ymmärtäminen on Componentan jokaisen työntekijän vastuulla. Keskeinen osa Componentan riskienhallintaa on whistleblowing-ilmoituskanava, jonka kautta työntekijät sekä muut sidosryhmät voivat raportoida yhtiön eettisten ohjeiden rikkomuksista, ja ihmisoikeuksien kunnioittamisen vastaiseen toimintaan liittyvistä epäilyistään.

Korruption ja lahjonnan torjunta

Componentan merkittävimmät riskit suhteessa korruption ja lahjonnan torjuntaan liittyvät tuotantoketjussa mahdollisesti tapahtuviin Componentan toimintaohjeiden vastaisiin toimenpiteisiin tai laiminlyönteihin. Reilu kilpailu on Componentalle tärkeä toimintaperiaate. Tämä koskee yhtiön käytöstä kilpailijoita ja asiakkaita kohtaan sekä toimintaa liike-elämässä. Componenta tai sen työntekijät ja muut Componentan nimissä toimivat tahot eivät saa tarjota, antaa tai ottaa vastaan lahjuksia tai muita laittomia etuuksia. Liikekumppaneille ja viranomaisten edustajille ei tule tarjota sopimattomia taloudellisia etuja Componentan liiketoimien tai yrityksen muiden etujen edistämiseksi.

Korruption ja lahjonnan torjunnan vastaisten sääntöjen laiminlyönti voi aiheuttaa Componentalle sanktio- ja maineriskin lisäksi taloudellisia menetyksiä, mikäli tuotantoketjun kumppaneita ei ole valittu kokonaistaloudellisesti oikein perustein. Yhtiön eettiset ohjeet sisältävät määräyksiä muun muassa lahjojen ja kestityksen antamisesta ja vastaanottamisesta sekä eturistiriitojen välttämisestä. Componenta on myös poliittisesti sitoutumaton yritys.

Korruptioon ja lahjontaan liittyvien riskien havaitsemiseksi ja torjumiseksi suunniteltu Componentan eettiset ohjeet koulutetaan tai käsitellään johdon, toimihenkilöiden ja työntekijöiden kanssa pääsääntöisesti kerran vuodessa. Tärkeänä pidetään, että henkilöstö ymmärtää käytännön työtehtävien tasolla, mitä lahjonta on ja miten sitä on torjuttava. Korruption ja lahjonnan vastaisessa toiminnassa merkittävä rooli on erityisesti Componentan osto- ja myyntiorganisaatioilla sekä yksiköiden ja yrityksen johdolla. Componentan eettisiä ohjeita koskevat koulutukset sisältävät korruption ja lahjonnan torjuntaan liittyviä käytäntöjä. Componentalla on erilliset eettiset ohjeet toimittajille ja alihankkijoille. Componenta on sitoutunut vastuulliseen liiketoimintaan ja rehellisyyteen. Componentan eettiset ohjeet auttavat toimimaan oikein, mikäli työntekijä kohtaa eettisen ongelman. Jokaista Componentan työntekijää kannustetaan nostamaan esille kysymyksiä yhtiön eettisiin ohjeisiin liittyen sekä ilmoittamaan mahdollisista havainnoista tai epäillyistä ohjeiden rikkomuksista. Myös yhtiön liikekumppanit ja muiden sidosryhmien edustajat voivat ilmoittaa tällaisista rikkomuksista tai niiden epäilyistä. Componentan whistleblowing-ilmoituskanava on keskeisessä roolissa myös mahdollisten korruptioon ja lahjontaan liittyvien epäilysten raportoinnissa.